ATHABASCA – Before the water we drink from the Athabasca River comes anywhere near our taps, it has already travelled hundreds of kilometres down the Rocky Mountains and halfway across the province on its way to the Peace-Athabasca Delta and eventually the Arctic Ocean.

It nourishes all organisms along the way and replenishes the land, picking up any number of natural and man-made contaminants along the way. That may sound like a modern-day kind-of-problem, but the quest for clean water, and the answer to why some water will make you sick, is something humans have been struggling with for thousands of years. Greek and Sanskrit writings from 4,000 years ago identify the need to heat, filter and strain water to make it consumable. Drawings found on Egyptian tombs from 2,500 years ago even show the process of coagulation with the use of alum, which captures suspended solids and brings them to the bottom of a collection of water, leaving the cleaner water at the top to be siphoned off and consumed.

Of course, this was long before the introduction of man-made chemicals and the discovery of micro-organisms, but many of the processes for water treatment that were developed thousands of years ago are still quite similar.

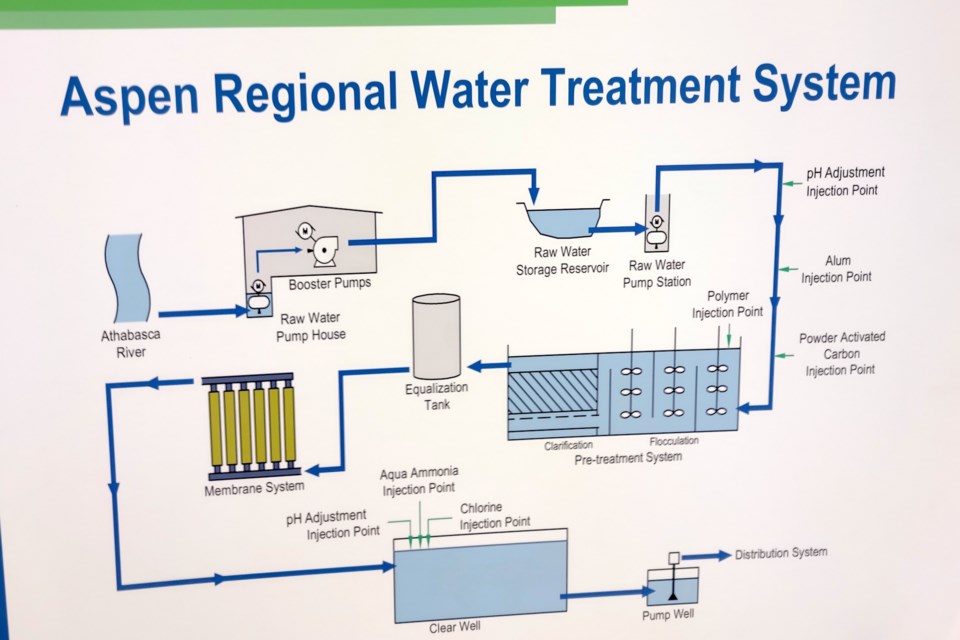

Today, we have multi-million-dollar software, devices and facilities that monitor any number of variables to make sure the water in our homes is safe to drink. It starts with the collection of the raw water — in Athabasca, the raw water intake system is currently part-way through a $5 million upgrade — which is pumped up the east hill to the Aspen Regional Water Treatment Plant, a state-of-the-art complex that brings the physics, chemistry and biology behind the science of water treatment together under one roof.

Now entering its second decade in operation, the new water treatment plant was completed in 2010 at a cost of $27 million dollars and cemented the partnership between the three municipalities — Town of Athabasca, Athabasca County and Village of Boyle — that still make up the Aspen Regional Water Services Commission. Eighty per cent of the project was covered through provincial grants, and it was built with the growth of the region in mind.

“The plant was oversized for the growth that looked like was going to happen, some of which we’ve had, but not the growth that was predicted at the time,” said ARWSC chair Kevin Haines, who was in his first term as an Athabasca County councillor at the time. “The plant is oversized for the region, which is a good thing because in 50 years, it'll still be doing its thing.”

After its journey through the water intake system and being transported to the treatment plant facility, the water is piped into the 74,000 cubic metre reservoir where it is stored before it is treated with chemicals and becomes the easily accessible potable water which we often don’t give a second thought. The size of the reservoir also allows operators the option to stop drawing from the river when raw water quality is poor, and use the stockpiled water in the reservoir instead.

The six-acre, five-metre deep reservoir is lined with a geosynthetic membrane and includes a fine bubble aeration system which is a form of pre-treatment that helps minimize the amount of chemicals used once the water is inside the building. A goose cannon is also used to scare away any birds that might try to make a stop in the reservoir.

The real journey is just beginning though.

The water from the reservoir is fed through a gravity pipe into the building. Once there, it’s pH is adjusted, turbidity (cloudiness) levels are measured, coagulant is added, along with powder activated carbon and then polymers, when necessary, to aid the coagulant before it enters the pre-treatment system where it is mixed thoroughly, clarified and sent to the equalization tanks.

“So, before the water goes into these tanks, we add some chemical, the primary chemical used is coagulant. There are various types, but it just basically neutralizes the charges and allows anything that's left in the water to clump together to increase its mass so it basically settles by gravity,” said water commission manager Jamie Giberson, as he and Haines provided a tour of the plant for the Advocate in July.

Chemicals are added in very precise amounts depending on the condition of the raw water that enters the plant. There is also a built-in fail-safe system for each chemical to make sure the additives are always available in the proper amounts and the process is never stalled.

Once it enters the pre-treatment system, the chemicals are mixed and the flocculation process begins as the coagulant goes to work and the remaining solids come together and sink to the bottom. The water then enters the clarification settling unit.

“The solids keep dropping to the bottom and the clear water is clarified and spills over into the holding tanks, before it goes into membrane filtration,” said Giberson.

The extra space in the facility has been set aside for future growth and more pre-treatment capacity should it ever be needed. About two-thirds of that space is currently being utilized.

Microfiltration membrane systems help remove the remaining particulate matter, and were developed with municipal water treatment in mind. The filtration modules force the water through hollow membrane fibres which allows for the passage of clean water, but larger contaminants are filtered out and removed as waste water.

The filters remove viruses and bacteria like Giardia and Cryptosporidium, microscopic parasites that still exist in untreated water, even in modern nations like Canada, and are the leading cause of waterborne illnesses across the world, and can sometimes be deadly. The filters also take care of oxidized iron and manganese and other organics that may be in the water, and also helps minimize the amount of flocculant additive and other chemicals that were used in the treatment process to this point.

Now, the water is nearly ready for distribution, but not before it is disinfected using chlorine and ammonia, and stored. The chlorine is added as the water enters the first underground cell, and as it flows over into the second cell, the ammonia is added, again very precisely, by chemical dosing pumps.

“This entire floor we're standing on, underneath is all water storage,” said Giberson as he explained the final steps of the treatment process. “This side is like one tank that's always full, that spills over a weir right into the other cell that has an operating level that goes up and down, and the reason for that is that is where we add the disinfection.”

Using both chlorine and ammonia to disinfect the water is called chloramination, which has been found to be a more suitable disinfection process as it results in fewer potentially toxic by-products then using chlorine alone. It is also more effective in protecting against viruses and bacteria, and does not affect the mineral content or pH level of the water.

Where does the water go from there? In Part 3, the distribution of the treated water will be in focus, as it is pumped out to residents of the town, village and several county hamlets.